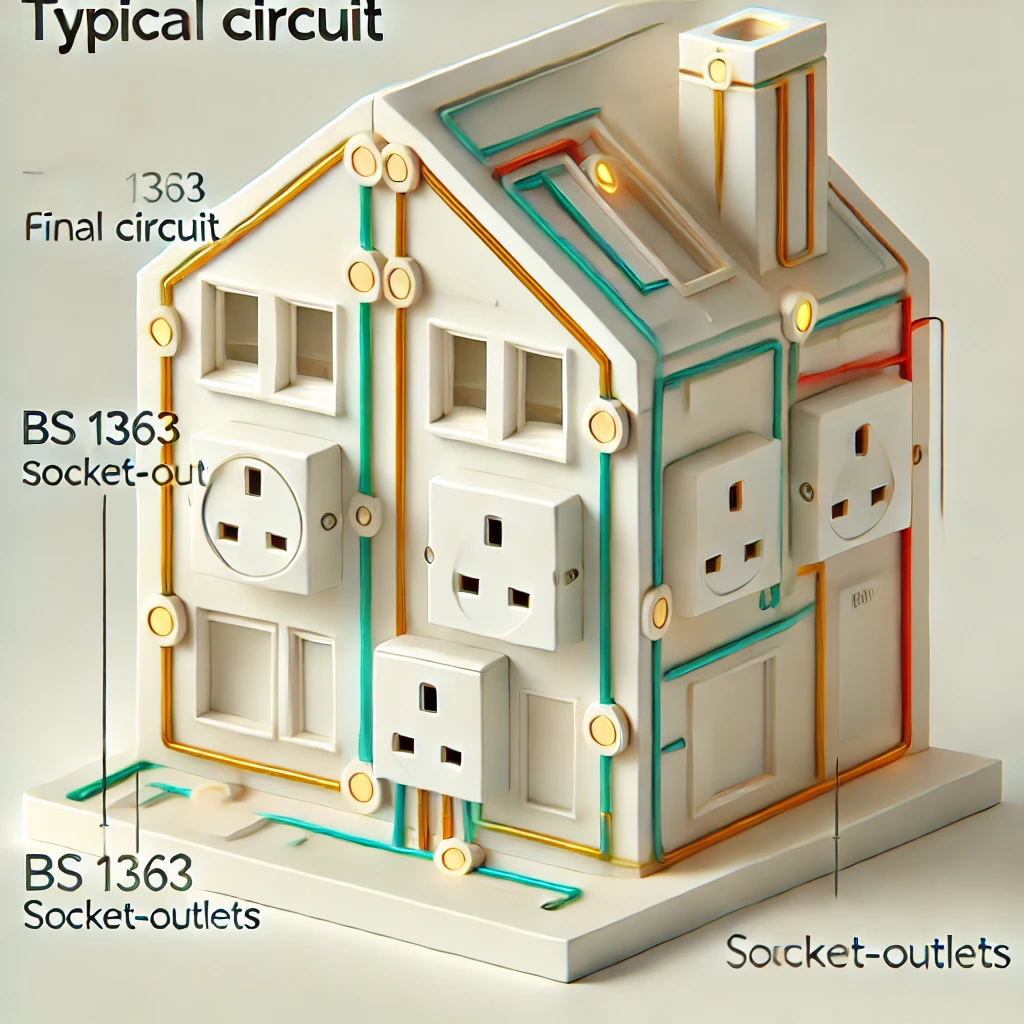

Understanding Typical Final Circuits Using BS 1363 Socket-Outlets in Household Installations

Regulation 553.1.7 outlines the guidelines for the number and positioning of socket-outlets in household installations. Learn how diversity is applied and the requirements for conductor sizes as per BS 7671.

OW London Electrician and Home Automation Engineers Team

Understanding Typical Final Circuits Using BS 1363 Socket-Outlets in Household Installations

Giudance Note 1, App.C Page 154

Diversity between socket-outlets and permanently connected equipment has already been taken into account in Table C1 and no further diversity may be applied."

Table C1: Typical Final Circuits Using BS 1363 Socket-Outlets in Household Installations

| Type of circuit | Overcurrent protective device rating (A) | Copper conductor thermoplastic or thermosetting insulated cables | Copper conductor mineral insulated cables | Maximum floor area served ‡ (m²) |

|---|---|---|---|---|

| A1 Ring | 30 or 32 | 2.5 | 1.5 † | 100 |

| A2 Radial | 30 or 32 | 4 | 2.5 † | 75 |

| A3 Radial | 20 | 2.5 | 1.5 † | 50 |

-

* The tabulated values of conductor size may need to be increased where more than two circuits are grouped together, but may be reduced for fused spurs. Table C1 applies to thermoplastic or thermosetting insulated cables of the types identified in Table 4A2 of Appendix 4 of BS 7671 in installation method C and method B and installed in accordance with those installation methods, and mineral insulated cable (MICC) as identified in Table 4G1A installed in accordance with reference methods C, E, F, and G of Table 4A2. It does not apply to 70 °C thermoplastic (PVC) insulated and sheathed flat twin cable with protective conductor installed in accordance with method A of Table 4D5.

-

† 1.5 mm² two-core MICC installed for a ring final circuit with a protective device rated at not more than 32 A or a radial circuit with a protective device rated at not more than 20 A may be taken as having a conductor not operating at a temperature above 70 °C and may be used to comply with the relevant requirements of Regulation 512.1.2. 1.5 mm² four-core MICC will not comply with Regulation 433.1.204 at 70 °C.

-

‡ The socket-outlets are to be as evenly distributed between circuits as is reasonable.

Visit Read more about A1, A2 and A3 size and other relative info .

C2.2 Circuit Protection

Table C1 is applicable for circuits protected by fuses to BS 3036 and BS 88 and circuit-breakers, Types B and C to BS EN 60898 or BS EN 61009-1 and BS EN 60947-2 and Types 1, 2, and 3 to BS 3871.

C2.3 Conductor Size

The minimum size of conductor in the circuit and in non-fused spurs is given in Table C1. However, if the cables of more than two circuits are bunched together or the ambient temperature exceeds 30 °C, the size of conductor is increased and is determined by applying the appropriate rating factors from Appendix 4 of BS 7671 such that the size then corresponds to a current-carrying capacity not less than:

- (a) 20 A for ring circuit A1;

- (b) 30 A or 32 A for radial circuit A2 (i.e. the rating of the overcurrent protective device); and

- (c) 20 A for radial circuit A3 (i.e. the rating of the overcurrent protective device).

The conductor size for a fused spur is determined from the total current demand served by that spur, which is limited to a maximum of 13 A.

Where a fused spur serves socket-outlets, the minimum conductor size is:

- 1.5 mm² for thermoplastic (PVC) or thermosetting insulated cables, with copper conductors; and

- 1 mm² for mineral insulated cables, with copper conductors.

Visit Read more about A1, A2 and A3 size and other relative info .

Regulation 433.1.204 states:

For a 30 A or 32 A ring final circuit with a protective device in accordance with the requirements of Regulation 433.1.204, supplying 13 A socket-outlets to BS 1363, a conductor with a minimum cross-sectional area (csa) of 2.5 mm² is deemed to comply with the requirements of Regulation 433.1.1 if the current-carrying capacity (Iz) of the cable is not less than 20 A and if, under the intended conditions of use, the load current in any part of the ring is unlikely to exceed for long periods the current-carrying capacity (Iz) of the cable.

Electrical accessories to BS 1363, etc., are designed for a maximum operating temperature at their terminals and also for use with thermoplastic (PVC) insulated conductors operating at a maximum conductor temperature of 70 °C.

Thermosetting cables can operate with conductor temperatures up to 90 °C and some types of mineral insulated cable can operate with conductor temperatures up to 105 °C.

Table 52.1

Such temperatures can damage accessories (see Regulation 512.1.5 of BS 7671). Consequently, when used, such cables must be derated to comply with this requirement (see note 1 of Table 4E2A, etc., of Appendix 4 of BS 7671).

Regulation 512.1.5

Such temperatures can damage accessories (see Regulation 512.1.5 of BS 7671).

Additional Notes:

- The tabulated values of conductor size may need to be increased where more than two circuits are grouped together but may be reduced for fused spurs. Table C1 applies to thermoplastic or thermosetting insulated cables of the types identified in Table 4A2 of Appendix 4 of BS 7671 in installation method C and method B and installed in accordance with those installation methods, and mineral insulated cable (MICC) as identified in Table 4G1A installed in accordance with reference methods C, E, F, and G of Table 4A2. It does not apply to 70 °C thermoplastic (PVC) insulated and sheathed flat twin cable with protective conductor installed in accordance with method A of Table 4D5. 1.5 mm² two-core MICC installed for a ring final circuit with a protective device rated at not more than 32 A or a radial circuit with a protective device rated at not more than 20 A may be taken as having a conductor not operating at a temperature above 70 °C and may be used to comply with the relevant requirements of Regulation 512.1.2. 1.5 mm² four-core MICC will not comply with Regulation 433.1.204 at 70 °C.

- † The socket-outlets are to be as evenly distributed between circuits as is reasonable.

Giudance Note 1, App.C Page 154

Frequently Asked Questions

Q: What is the maximum number of socket-outlets allowed on a ring final circuit?

A: According to Regulation 553.1.7, there is no specific maximum number of socket-outlets, but they must be positioned to ensure compliance with the regulation. Each socket-outlet in a twin or multiple socket-outlet unit is considered as one socket-outlet.

Q: How is diversity applied to socket-outlets in household installations?

A: Regulation 553.1.7 states that diversity between socket-outlets and permanently connected equipment has already been considered in Table C1, so no further diversity may be applied.

Q: What is the minimum conductor size for a radial circuit protected by a 20 A overcurrent device?

A: As per Table C1 and in accordance with Regulation 553.1.7, the minimum conductor size for a radial circuit with a 20 A protective device is 2.5 mm² copper conductor thermoplastic or thermosetting insulated cables, or 1.5 mm² copper conductor mineral insulated cables.

Q: Can 1.5 mm² mineral insulated cable (MICC) be used in a ring final circuit?

A: Yes, according to the additional notes in Table C1 and Regulation 553.1.7, 1.5 mm² two-core MICC can be used for a ring final circuit with a protective device rated at not more than 32 A, provided the conductor does not operate at a temperature above 70 °C.

Q: What installation methods apply to the conductor sizes listed in Table C1?

A: The values in Table C1 apply to thermoplastic or thermosetting insulated cables identified in Table 4A2 of Appendix 4, installed using installation methods C and B, and to mineral insulated cable (MICC) identified in Table 4G1A, installed according to reference methods C, E, F, and G.

Giudance Note 1, App.C Page 154

What users Saying

Discover what our customers think about our services. Their feedback reflects our commitment to delivering exceptional service and expert solutions for all electrical and security needs.