What types of earth electrodes are recognized for use in electrical installations?

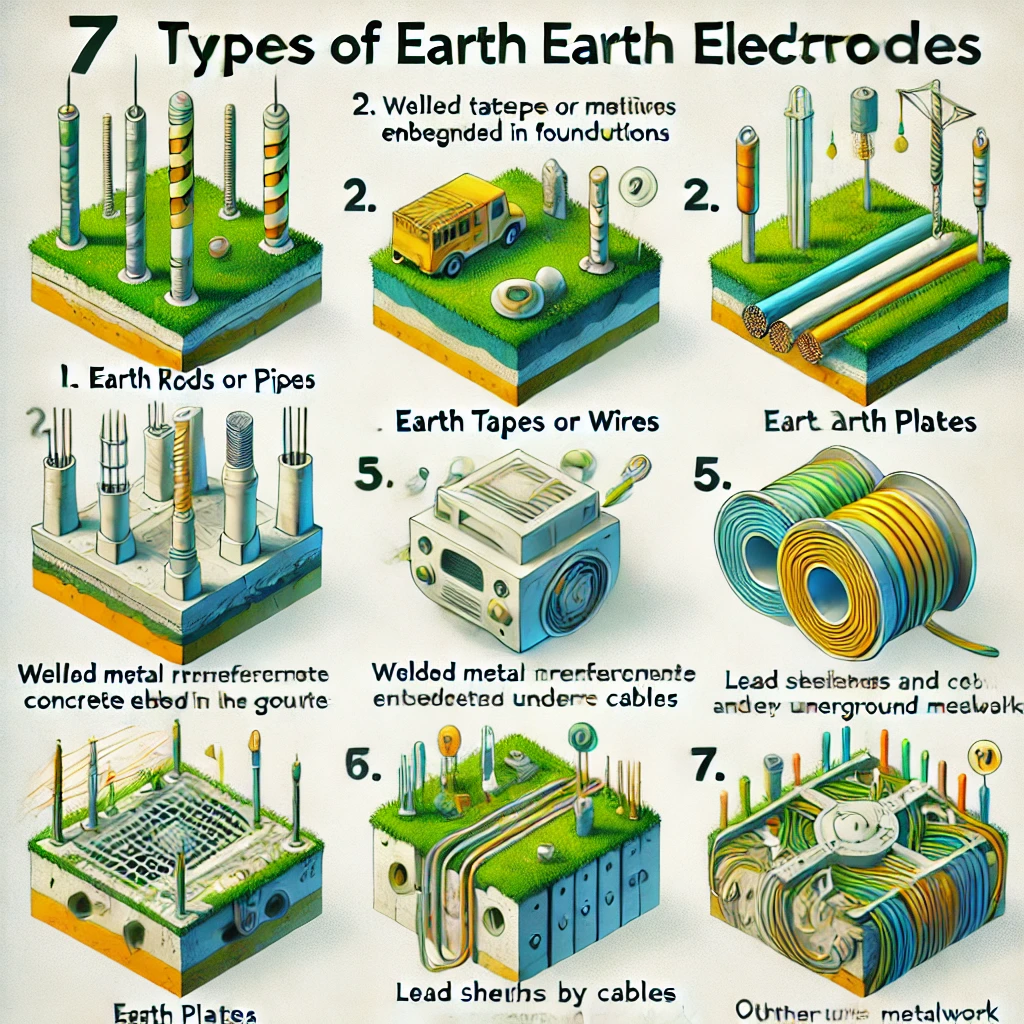

BS 7671 Regulation 542.2.2 identifies seven types of suitable earth electrodes for use in electrical installations.

OW London Electrician and Home Automation Engineers Team

What types of earth electrodes are recognized for use in electrical installations?

Regulation 542.2.2 states:

"The following types of earth electrodes are recognized as suitable for providing a low-resistance path to earth:

- (i) Earth rods or pipes

- (ii) Earth tapes or wires

- (iii) Earth plates

- (iv) Underground structural metalwork embedded in foundations

- (v) Welded metal reinforcement of concrete (excluding pre-stressed concrete)

- (vi) Lead sheaths and other metal coverings of cables (where not restricted)

- (vii) Other suitable underground metalwork"

These types of earth electrodes are essential for ensuring electrical safety and system stability in various installation environments.

Frequently Asked Questions

Q: How deep should earth rods be installed?

A: According to BS 7671 Regulation 542.2.2, earth rods must be driven deep enough to ensure low earth resistance and stability. Typically, this is at least several feet, depending on soil conditions. Doubling the depth can often achieve a significant reduction in resistance.

Q: Can I use the metal frame of a building as an earth electrode?

A: Yes, the metal frame of a building can be used as an earth electrode if it meets the criteria specified in Regulation 542.2.2 (iv) and is adequately connected to the earth.

Q: What are the considerations for soil resistivity in earth electrode installation?

A: Soil resistivity, influenced by factors such as soil composition, moisture content, and temperature, plays a crucial role in determining the effectiveness of an earth electrode. For example, clay soil with high moisture content has lower resistivity, making it more suitable for earthing purposes. Proper installation should consider these factors to ensure the earth electrode provides a stable connection to earth.

Q: What is the importance of the connection between the earthing conductor and the earth electrode?

A: The connection must be electrically and mechanically sound to ensure reliability. Proper clamps and protective measures against corrosion are essential to maintain a low-resistance path to earth. It's also necessary to ensure that connections are accessible for inspection and testing.

For more detailed guidance and technical insights, referring to BS 7430: 2011+A1:2015, which provides recommendations on protective earthing of electrical installations, can be beneficial.

What users Saying

Discover what our customers think about our services. Their feedback reflects our commitment to delivering exceptional service and expert solutions for all electrical and security needs.