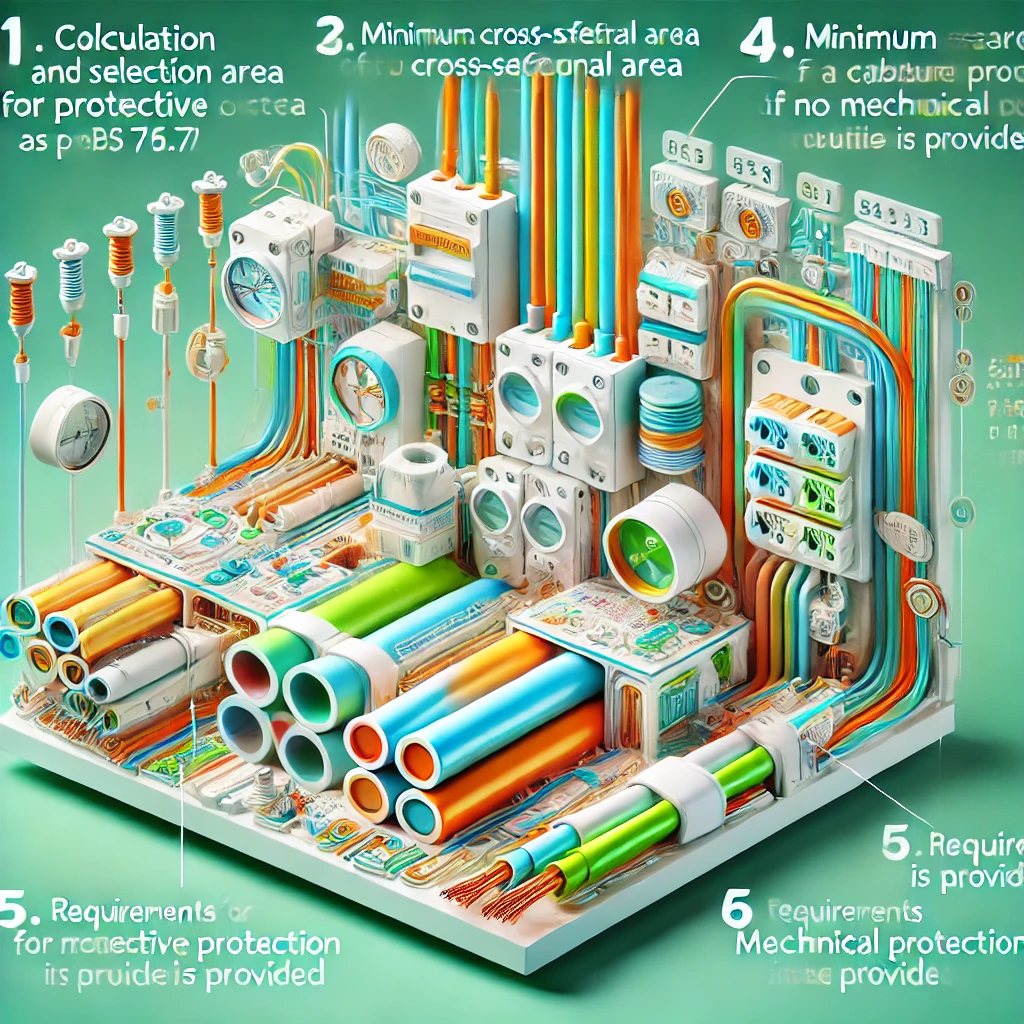

What is the Minimum Cross-Sectional Area for Protective Conductors?

According to BS 7671, Regulation 543.1.1 outlines the requirements for the minimum cross-sectional area for protective conductors. This regulation specifies the methods for calculating or selecting the appropriate size based on various conditions, including mechanical protection and the nature of the installation.

OW London Electrician and Home Automation Engineers Team

What is the Minimum Cross-Sectional Area for Protective Conductors?

Regulation 543.1.1 states:

Regulation 543.1.1 outlines the requirements for the minimum cross-sectional area for protective conductors. This regulation specifies the methods for calculating or selecting the appropriate size based on various conditions, including mechanical protection and the nature of the installation.

In simpler terms, the regulation states that:

Calculation and Selection:

The cross-sectional area of the protective conductor can either be calculated based on specific conditions (short-circuit current) or selected from predetermined values.

When Calculation is Needed:

If the choice of the cross-sectional area of line conductors depends on the short-circuit current considerations, and the earth fault current is expected to be less than this, then detailed calculations as per Regulation 543.1.3 must be performed.

Minimum Cross-Sectional Area Requirements:

If the protective conductor is not part of a cable, conduit, ducting, trunking, or any enclosed wiring system, the minimum sizes are specified:

- 2.5 mm² copper if there is protection against mechanical damage.

- 4 mm² copper if there is no mechanical protection.

Buried Conductors:

Additional rules apply to conductors buried in the ground, as per Regulation 542.3.1, which ensures they comply with earthing conductor requirements.

Frequently Asked Questions

Q: Why is it important to have a minimum cross-sectional area for protective conductors?

A: According to Regulation 543.1.1, the minimum cross-sectional area ensures that the conductor can safely carry fault current without excessive heating, preventing damage to the electrical installation and reducing the risk of fire.

Q: What is considered mechanical protection for a protective conductor?

A: Mechanical protection typically includes conduits, trunking, or other enclosures that shield the conductor from physical damage. If such protection is in place, a smaller cross-sectional area may be used, as specified in Regulation 543.1.1.

Q: Are there specific materials required for protective conductors?

A: Yes, the regulation specifies "copper equivalent," meaning the conductor should have equivalent electrical conductivity to copper. This ensures consistent performance in fault conditions, as per Regulation 543.1.1.

Q: Can aluminum be used instead of copper for protective conductors?

A: While the regulation mentions "copper equivalent," it implies that if an alternative material like aluminum is used, it must match the electrical performance of the specified copper size, considering factors like conductivity and mechanical strength, as indicated in Regulation 543.1.1.

Understanding these requirements helps ensure the safety and reliability of electrical installations by ensuring protective conductors can handle fault currents appropriately and prevent potential hazards.

What users Saying

Discover what our customers think about our services. Their feedback reflects our commitment to delivering exceptional service and expert solutions for all electrical and security needs.