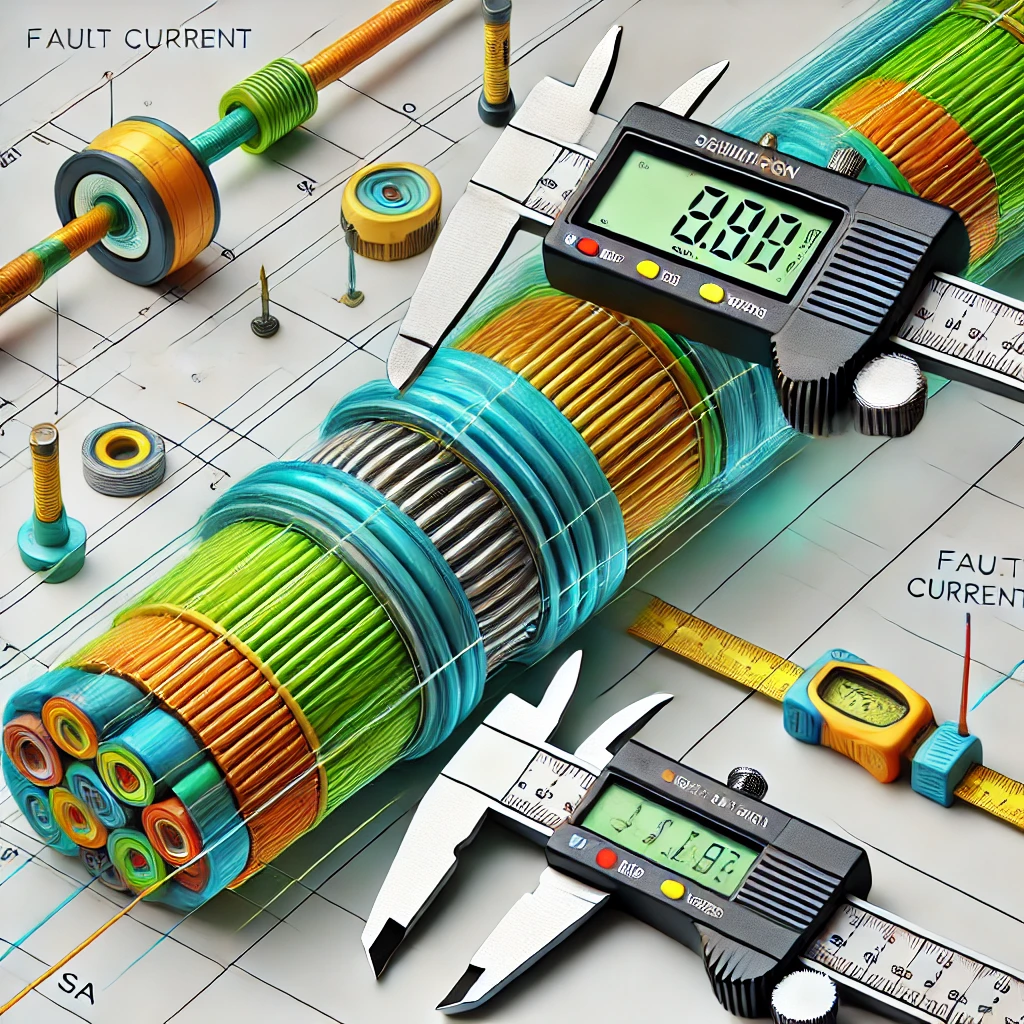

How to Calculate the Cross-Sectional Area of a Conductor for Fault Current Conditions

The regulation states that the size (cross-sectional area) of the conductor must be large enough to handle the potential fault current without overheating or damage. The formula provided helps calculate the minimum size required based on several factors I (Fault Current) The maximum current expected during a fault, measured in amperes.Regulation 543.1.3

OW London Electrician and Home Automation Engineers Team

How to Calculate the Cross-Sectional Area of a Conductor for Fault Current Conditions

Regulation 543.1.3 states:

"The cross-sectional area, where calculated, shall be not less than the value determined by the following formula or shall be obtained by reference to BS 7454:

𝑆 = √(𝐼² * 𝑡) / 𝑘"

Note: This equation is an adiabatic equation and is applicable for disconnection times not exceeding 5s.

Where:

- S is the nominal cross-sectional area of the conductor in mm².

- I is the value in amperes (rms for AC) of fault current for a fault of negligible impedance, which can flow through the associated protective device, due account being taken of the current limiting effect of the circuit impedances and the limiting capability (𝐼²𝑡) of that protective device.

- t is the operating time of the protective device in seconds corresponding to the fault current I amperes.

- k is a factor taking account of the resistivity, temperature coefficient, and heat capacity of the conductor material, and the appropriate initial and final temperatures.

This regulation specifies that the size (cross-sectional area) of the conductor must be sufficient to handle the potential fault current without overheating or damage. The formula provided helps calculate the minimum size required based on several factors:

Variables in the Formula:

- S (Cross-Sectional Area): The nominal cross-sectional area of the conductor in mm².

- I (Fault Current): The maximum current expected during a fault, measured in amperes (rms for AC).

- t (Disconnection Time): The time in seconds it takes for the protective device (like a circuit breaker) to disconnect the fault current.

- k (Material Factor): A constant that varies depending on the material of the conductor, its initial and final temperatures, and other thermal properties.

Simplified Explanation:

The regulation ensures safety by preventing the conductor from overheating and possibly causing a fire during a fault. The adiabatic equation is used to calculate the minimum cross-sectional area needed based on the fault current, the disconnection time of the protective device, and the material properties of the conductor.

Frequently Asked Questions

Q: Why is the adiabatic equation used for disconnection times not exceeding 5 seconds?

A: According to Regulation 543.1.3, the adiabatic equation assumes that there is no heat loss to the surroundings during the fault condition, which is a reasonable assumption for short durations (up to 5 seconds). For longer durations, heat dissipation needs to be considered, making this formula less accurate.

Q: What is the 'k' factor and how is it determined?

A: Regulation 543.1.3 specifies that the 'k' factor is a constant depending on the material of the conductor (e.g., copper, aluminum), its temperature characteristics, and its initial and final temperatures. These values are typically provided in tables within standards like BS 7671 or related documents.

Q: How does this regulation ensure safety?

A: Regulation 543.1.3 ensures safety by specifying that the conductor's cross-sectional area is sufficient to handle fault currents without exceeding safe temperature limits. This minimizes the risk of insulation damage, fires, and other hazards.

What users Saying

Discover what our customers think about our services. Their feedback reflects our commitment to delivering exceptional service and expert solutions for all electrical and security needs.